An often underlooked and underestimated piece of juicing equipment for a commercial cold press juicer is the press plates, yet the difference between good and bad press plates can literally mean success or failure for your business.

In a nutshell, the press plates are the two high density plastic boards that the press bag sits between, and they are the contact point with the bag during the press process. Given that they are the only contact point with the bag, it is essential that they are formed to squeeze as much juice out of the bag as possible. What’s the point of having all that force from the press if the bag isn’t being squeezed properly?

The first key element of the bag design is the interlocking of the press plates. This can been seen below, and we can see from the photo that the plates fit together to ensure the bag has as much surface area squeezed as possible.

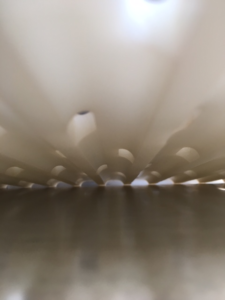

Another special feature in our press bag design is the holes in the press plates. This allows the juice to flow out of the bag and through holes into the channels on the press plate. This is shown in the photo below with a press plate being held against the platen. Can you see how the juice can pass through the holes then flow down the channels into the juice pan?

If you would like to know more about this or have any questions please do get in touch.

3 Comments

Delethia

Please send a price list for your commercial juicers. Also include how many gallons each juicer produce per hour.

andrew

Hi,

Thanks for getting in touch. One of our account executives will be in touch with you shortly.

Juris

Please send me a price for press plates. Thanks

Leave a Reply